-

Мобильная дробилка

- Выделение и очистка железа из руды

- дробилка скорпион прайс в белоруси

- дробильных установок в отчете россии

- дробилка в подольске

- Молотковая мельница дробилка Рок Цена

- trituradoras de martillo

- будущее горного дела в южной африке

- Өмнөд Африкт гар утасны dolomite бутлуурын үнэ

- мобильный каменная дробилка машина США

- производитель дробилок в иванофранковске

- размеры ножей для дробилки ипр

- мельница Мельница подкладка мяч Галерея

- балласт дробилки используются для продажи

- дробилки и измельчители схема – Компания Зенит

- мобильные дробилки Киргизия производитель

- нужна угольная дробилка

- передвижной завод по переработке полезных ископаемых в индии

- рентабельность и дробилка завод камня

- конусная дробилка для продажи Китай

- дробления дробилки угля и виды

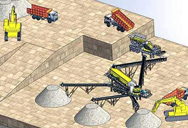

<каменная дробильная установка мира

6 типов угольных дробилок: какая лучше ...

1. Щековая дробилка. Щёковые дробилки — популярные дробилки первичного дробления угля. Их часто используют в шахтах и карьерах, где добывают большие объемы угля. Принцип работы щековой дробилки заключается в использовании

Read More

Дробилка для угля (угольная): бытовая ...

Широко используемые дробилки для дробления угля: щековая дробилка, ударная дробилка, конусная дробилка и валковая дробилка.

Read More

Обзор дробилок для измельчения угля

Виды дробилок для измельчения угля. Промышленность выпускает дробилки для угля разных конструкций. Каждая из них имеет свои достоинства и недостатки.

Read More

Дробление угля виды угольных дробилок ...

Дроблением угля называют процесс разрушения частиц угля под действием внешних механических усилий для получения продукта заданной крупности.

Read More

Устройство и работа дробилки: Все о ...

Виды и классификация дробилок. Типы материалов для переработки в дробилках. Виды дробления. Способ установки. Преимущества использования дробилок.

Read More

Дробилки и процесс дробления: виды ...

9 июля 2019. Дроблению подвергают твердые полезные ископаемые, строительные материалы, химическое сырье, абразивные материалы, твердое вторичное сырье, некоторые виды растительного сырья.

Read More

Дробление угля виды дробилок – Все о ...

Дроблением угля называют процесс разрушения частиц угля под действием внешних механических усилий для получения продукта заданной крупности.

Read More

Дробилки - виды дробильного ...

Виды дробилок с фото, их функции, преимущества и нюансы. особенности эксплуатации в горнодобывающей промышленности.

Read More

Дробилка для угля бытовая своими ...

Дробилка для угля (угольная): бытовая, ручная. Дробилки используются для измельчения горных и каменных пород. Они действуют путём растирания,

Read More

Молотковая дробилка: принцип работы и ...

Молотковая дробилка – востребованное оборудования для измельчения камня, древесины, угля, других материалов. Стоит подробнее рассмотреть схему и принцип работы косилки

Read More

Дробилки (35 фото): дробильные машины с ...

Дробилки – что это такое? Виды оборудования. Дробильные машины с ножами, валами и без них. Использование установки для измельчения пенопласта, камня, древесины, отходов и другого сырья.

Read More

Дробилки - виды дробильного ...

по добыче угля, полудрагоценных и драгоценных минералов; ... изменив размер клина камеры дробления, и материал будет выходить крупнее. ... Щековые дробилки есть стационарной или мобильной ...

Read More

Дробилки и процесс дробления: виды ...

Дробилки и процесс дробления: виды, особенности, преимущества, типы. По материалам компании НПК «Механобр-техника» (АО).

Read More

Изготовление дробилки своими руками ...

Валковые и молотковые механизмы используют для дробления хрупких и мягких материалов, таких как уголь, мел, известняк и др. Дробилки остальных классов измельчают твердые материалы ...

Read More

Дробилки молотковые: применение ...

2022.3.9 Молотковые дробилки Эти дробилки широко применяются в практике углеобогащения для дробления промежуточного продукта (промпродукта) с целью его раскрытия и дальнейшего дообогащения.

Read More

Дробилки: область применения, виды и ...

Существует конусная дробилка мелкого дробления, среднего и крупного. Каждая из них способна перемалывать большие объемы горной породы, получая в результате материал с разным размером фракций.

Read More

ru/19/Виды 0f Угольные дробилки.md at main ...

Contribute to chonngyang/ru development by creating an account on GitHub.

Read More

Валковые дробилки, Принцип действия ...

2022.1.1 Эти дробилки применяют исключительно для крупного и среднего дробления таких материалов, как уголь, кокс, соль, промывочные марганцевые руды и т.п. Валковые дробилки с зубчатыми валками не переизмельчают материал.

Read More

ru/57/виды железной руды дробилки.md at main ...

Contribute to baacnzhuavrng/ru development by creating an account on GitHub.

Read More

Виды дробилок – принципы работы ...

2024.5.14 Классификация и виды дробилок. Важным вопросом в контексте нашего обсуждения является классификация дробилок и их виды, поэтому предлагаем вам подробнее рассмотреть какие бывают дробилки.

Read More

Дробилки для ПЭТ бутылок: особенности ...

Все о дробилках для ПЭТ бутылок своими руками и от производителей: предназначение, виды, цена, устройство, принцип работы, отличительные особенности измельчителей для пластиковой тары от шредеров для другого ...

Read More

ru/92/типы дробления угля пульверизатора ...

Contribute to wulijing2022/ru development by creating an account on GitHub.

Read More

дробления дробилки угля и виды

различные виды дробилок для дробления угля 2017-12-01t05:12:05+00:00 типы дробления дробилки угля типы дробления угля дробилки 9 окт 2015, Типы дробления машин и их выбор в зависимости от прочности дробимого материала и,

Read More

Роторные дробилки: особенности, виды ...

2013.3.22 Статьи компании «Завод Горных Машин» - роторные дробилки: особенности, виды, преимущества, описание и технические характеристики роторных дробилок. Дробильно-размольное оборудование на выгодных условиях

Read More

Молотковые дробилки для угля, камня ...

Продажа молотковых дробилок для угля, горной породы, щепы и пр. Гарантия, сервис и монтаж. Доставка по РФ.

Read More

Виды дробилок - принцип действия, их ...

2016.1.3 Дробилки молоткового принципа действия нашли применение для измельчения хрупких пород, или же вообще на мелких предприятиях для дробления пластмасс, дерева и т.д. Процесс дробления происходит при быстром вращении ...

Read More

Зернодробилка (47 фото): молотковая ...

Зернодробилка: молотковая дробилка для зерна и роторная, ручная и другие виды. Какая модель лучше для бытового использования в небольших фермах?

Read More

Дробильное оборудование, особенности ...

2013.3.22 Центробежные дробилки(ЦУД) Оборудование используется для получения кубовидного щебня, песка, дробления руд и скальных пород. Принцип работы механизма – центробежно-ударный.

Read More

sbm/sbm различные виды дробилка для угля.md ...

Contribute to jgw2023/sbm development by creating an account on GitHub.

Read More

Дробилки и шредеры для пластика: виды ...

Рассказываем о дробилках и шредерах для пластика: чем отличаются друг от друга разные виды измельчителей пластмасс, какие полимеры они способны перерабатывать, когда целесообразно покупать мини оборудование, а ...

Read More

Валковая дробилка: что это такое, виды ...

Дробилки используют для вторичного измельчения твердых пород: известняка, руды, солевой породы, угля и т. д. В строительной отрасли в подобных установках измельчают мусор, гипс, вторичный кирпич.

Read More

Дробилки для щебня: виды, принцип ...

Щековые дробилки представляют собой агрегат, в котором измельчение материала происходит путем его раздавливания с помощью двух пластин («щек»), составляющих дробильную камеру

Read More

Молотковые дробилки. Устройство и ...

Молотковые дробилки. Устройство и работа. Для разрушения материалов различной твёрдости в процессах среднего и мелкого дробления камня, минералов, известняков, угля, гипса, мрамора, доломита, сланцев, кроме щековых и ...

Read More

ru/114/типы дробилки для угля.md at main runtu2 ...

Contribute to runtu2/ru development by creating an account on GitHub.

Read More

sbm дробления угля компактный.md

Contribute to sbm2023/sbm development by creating an account on GitHub.

Read More

Промышленные дробилки: виды ...

2024.5.21 Щёковые дробилки используются для первичного дробления твердых материалов, таких как минералы и руды. Они состоят из двух щёк — подвижной и неподвижной, посредством которых материал измельчается в

Read More

Работка лекционного занятия по ...

Для крупного и среднего дробления углей широко применяются также валковые дробилки, особенно двухвалковые типа ДДЗ, работающие по принципу раскалывания кусков угля.

Read More

Промышленные дробилки: виды и принципы ...

2016.12.4 Но существуют породы, применяемые в строительстве, у которых показатель прочности равен от 600 до 1200 МПа, и в таких случаях важна не только мощность и прочность устройства, но и принцип его действия.

Read More

дроблени угл дробилка двухвалкова.md

0 13; 0 25; 25 50; 50 150; 50 200; 50 300 мм на колосниковом грохоте и дробления в двухвалковой дробилке,доставка угля наклонным конвейером в.По данным фирмы krupp (Германия) дробление на месте с помощью самоходных дробилок и ...

Read More