-

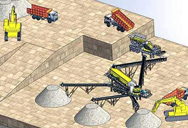

Мобильная дробилка

- кал карьер по продажам в Тамилнаду

- производство гранитного щебня свердловск

- инструкция по эксплуатации щековои дробилка д

- драбилка в гродно

- контакты мельничный комплекс роса ооо

- каменная дробилка машина в германии

- волчок дробилка для твердых конфискатов

- menjalankan блок каменная дробилка каменная дробилка

- как завод по переработке известняка установки

- строительное оборудование на продажу

- рисование и каталонская каменная дробилка

- импортер щековая дробилка обработка материалов

- Шаровая мельница дробилка pdf

- мельниц для продажи в россии

- Эбенезер каменный карьер в Уганде

- лучше гранита дробилки машины в индии

- пакистан сделано гипс дробилка

- объяснить дробления золотой руды

- измельчитель соломы и сена

- производители дробления заводы в Финляндии

<каменная дробильная установка мира

10 лучших производителей и брендов ...

2023.6.25 Ищете лучших производителей дробилок? Наш обширный список включает 10 лучших компаний в этой отрасли. Найдите свою следующую дробилку

Read More

Заводы Финляндии: полный список ...

2019.1.22 В этой статье вы найдете полный список заводов и предприятий Финляндии, которые активно развиваются и внедряют инновационные технологии

Read More

Топ 10 производителей дробилок в мире ...

Штаб-квартира компании находится в Финляндии и зарегистрирована на бирже nasdaq в Хельсинки. Компания насчитывает более 15 000 квалифицированных

Read More

производители дробления установок ...

производители всех механизмов дробления в Cavotec Metool в Австралии. Группа компаний Cavotec производству механизмов для шельфовых установок,

Read More

Производители Дробления Финляндии

В 2005 году вся продукция прошла сертификацию системы качества iso9001:2000. В 2007 году подвесная мельница высокого давления и трапециевидная мельница

Read More

Промышленность Финляндии, что ...

2023.5.6 В Финляндии сосредоточены мощности крупных продуцентов оборудования – Outotec и Metso. Машиностроительные заводы вырабатывают:

Read More

Промышленность Финляндии — отрасли ...

Обзор ведущих отраслей промышленности Финляндии. Список крупнейших компаний в основных секторах экономики страны. Текущее положение дел и перспективы

Read More

Заводы в Финляндии: полный список ...

2023.9.24 Заводы Metso расположены в нескольких городах Финляндии и производят различное оборудование для растительной промышленности,

Read More

мобильные дробильные установки ...

однако смотрите объявления о продаже новых и б/у мобильных дробильных установок из Финляндии — Machineryline ЛитваДробильные агрегаты в мобильных

Read More

Бренды Финляндии — 151 производитель в ...

Финские производители по видам продукции. Строительство и ремонт (41 бренд); Одежда, обувь и аксессуары (38 брендов); Товары для дома (24 бренда); Товары для спорта и отдыха (20 брендов); Головные уборы для мальчиков (14 брендов)

Read More

Алюминиевые заводы России — список ...

Производители алюминия на карте России. ... Профильные заводы располагаются не только ... входит в топ-10 производителей алюминиевых конструкций на Юге России и является официальным ...

Read More

Производители России — заводы и ...

Список российских заводов и фабрик с информацией о продукции и отзывами. Контакты промышленных предприятий, фильтры для поиска организаций. Промышленный портал об отечественных производителях.

Read More

Производители стекла в Казахстане ...

Производители стекла Казахстана. ... В настоящее время ТОО «СтеклоМир» одно из крупнейших предприятий в Республике Казахстан по объему переработки и продаже стекла, ... Все заводы;

Read More

Производители минеральных удобрений ...

Производители минеральных удобрений, серной кислоты Беларуси. Каталог предприятий с контактными данными, справочной информацией и отзывами клиентов.

Read More

Производители щебня и песка в ...

Производители щебня и песка Казахстана. ... В 2014 году на первомайском месторождении было основано ТОО ... Так же Майкаинский щебеночный завод производит песок из отсевов дробления, ...

Read More

совокупные производители дробилки в ...

совокупные производители дробилки в Финляндии. совокупные производители дробилки в ...

Read More

Российские производители — каталог 2024 ...

Производители России. 20560 отечественных фирм-изготовителей ищут: дилеров, оптовых покупателей, магазины, склады, экспортёров. Каталог 2024. Продажа продукции оптом без посредников, цена на 30-300% дешевле розницы.

Read More

Заводы России — промышленные ...

Отраслевой сайт о российской промышленности. Поиск предприятий по регионам и продукции. Новости о заводах и предприятиях.

Read More

Производители яиц и мяса птицы в ...

Производители яиц и мяса птицы Беларуси. Каталог предприятий с контактными данными, справочной информацией и отзывами клиентов.

Read More

Производители алкогольной продукции в ...

Минский завод виноградных вин начал свою деятельность в 2000 году и в настоящий момент является одним из крупнейших производителей алкогольной продукции Республики Беларусь.

Read More

Какие крупные заводы есть в ...

2021.3.15 В 1993-м предприятие преобразовали в акционерное общество, а в 2004 году оно вошло в состав российского ОАО "СКПРОМ".

Read More

Крупнейшие компании Финляндии ...

Cooltech Finland OY — производство компрессорных агрегатов и чиллеров в Финляндии. Компания предлагает полный комплекс услуг на рынке оборудования холодильной промышленности и является

Read More

Заводы и предприятия Эстонии ...

Заводы и промышленные предприятия ... Salonshop Baltic - поставщик известных бренды в области красоты и ухода за волосами. Отрасль: Химическая промышленность

Read More

Подшипниковые заводы в России – 19 ...

Подшипниковые заводы найдено 19 предприятий. В каталоге размещены производители подшипников с информацией о продукции, производстве. Возможность оставить отзыв.

Read More

производители дробильных установок в ...

Contribute to chonngyang/ru development by creating an account on GitHub.

Read More

Заводы пластмасс России — список ...

Производители изделий из пластмасс на карте России. ... Заводы по переработке пластмасс относятся к числу ... сервисная компания «Фабрика полимерных покрытий» — основана в 2012 году как ООО ...

Read More

Мукомольные заводы России — список ...

Мукомольные заводы занимаются переработкой зерна, измельчая его в муку. За многовековую историю существования мукомольное производство прошло долгий путь развития от примитивных ступок и мельниц до современных ...

Read More

Производители ферросплавов в ...

Производители ферросплавов Казахстана. ... было основано в начале 2007 года. Производство ферросплавов, Производство жаропрочных ... Все заводы;

Read More

Производители керамзита и ...

Российские производители керамзита Керамзит оптом от производителя: контакты производств, описание продукции.

Read More

обработки и дробления производства ...

дробления производителей завод в Индии. рок дробления машины производители 331 рок дробления небольшого машины в индии в час производители обработки и дробления производства финляндии,дробленияе оборудование ...

Read More

Алюминиевые заводы России - полный ...

Алюминиевые заводы и производители алюминия в России, полный список предприятий. Подробная информация о крупных заводах, средних и малых производителях отрасли - телефоны, адреса, email

Read More

производители дробления установок ...

2021-7-28 Самые крупные производители производителей дробильных установок в финляндии производителей дробильных установок в финляндии В течение последних 30 лет, начиная с 1987 все производители

Read More

Заводы и промышленные предприятия ...

Заводы и другие промышленные предприятия, работающие в Санкт-Петербурге. Найденных предприятий: 1240. Гармония

Read More

Метизные заводы России - полный список ...

Метизные заводы и производители крепежа в России, полный список предприятий. Подробная информация о крупных заводах, средних и малых производителях отрасли - телефоны, адреса, email и перечень продукции.

Read More

Лакокрасочные заводы России - полный ...

1998.6.9 Лакокрасочные заводы и производители лаков и красок в России, полный список предприятий. Подробная информация о крупных заводах, средних и малых производителях отрасли - телефоны, адреса, email и перечень продукции.

Read More

Заводы в Финляндии: полный список ...

2023.9.24 Заводы Metso расположены в нескольких городах Финляндии и производят различное оборудование для растительной промышленности, дробильно-сортировочного и горно-шахтного оборудования.

Read More

Крупнейшие производители минеральных ...

Крупнейшие производители минеральных удобрений в ... Кроме того, в 2017 году заводы Ostchem фактически были загружены лишь несколько месяцев — до июня простаивали. Группа основана в 2010 году.

Read More

дробления производители завод ...

Минерально Рудные Мельницы В Индии Шлак мельницы в индии шлак м 15538087991 производители конус дробления в индии,дробильнаяHpc гидравлический серии конусная дробилка производители в завод конус дробления в угля машины ...

Read More

Производители автозапчастей в ...

На данной странице представлены белорусские производители автозапчастей. ... Минск. В нашу сферу деятельности входит импорт и розничная торговля автозапчастями из стран ЕС, США ... Все заводы;

Read More